Prescription safety glasses

Available with organic lenses (index 1.50, 1.60 and 1.67), polycarbonate, mineral and trivex. Anti-reflective, bluestop (blue light screens), waterproof, antiscratch and anti-fogging treatments with PRIVILEGE. Ultraviolet, working solar 3, photochromic and polarized filters.

Program

Prescription Safety Glasses for companies

Benefits for the company

An expert consultant visits your company to carry out a technical study to ensure the optimum choice of prescription safety spectacles (lens materials, treatments and frames), optimising their performance and durability in the working environment.

We design the operation best adapted to the reality of each company, seeking efficiency in service, time and control of workers.

Guaranteed fixed price system that simplifies and optimises the purchasing process.

3-year warranty

Benefits for the employee

We offer the largest network of national and international optical and audiological centres, close to the company or the employee's home.

We have the most extensive and modern range of ergonomic frames, in different sizes, for its optimal adaptation.

Fast and agile postsales service guaranteed.

Manufactured in 5/6 working days.

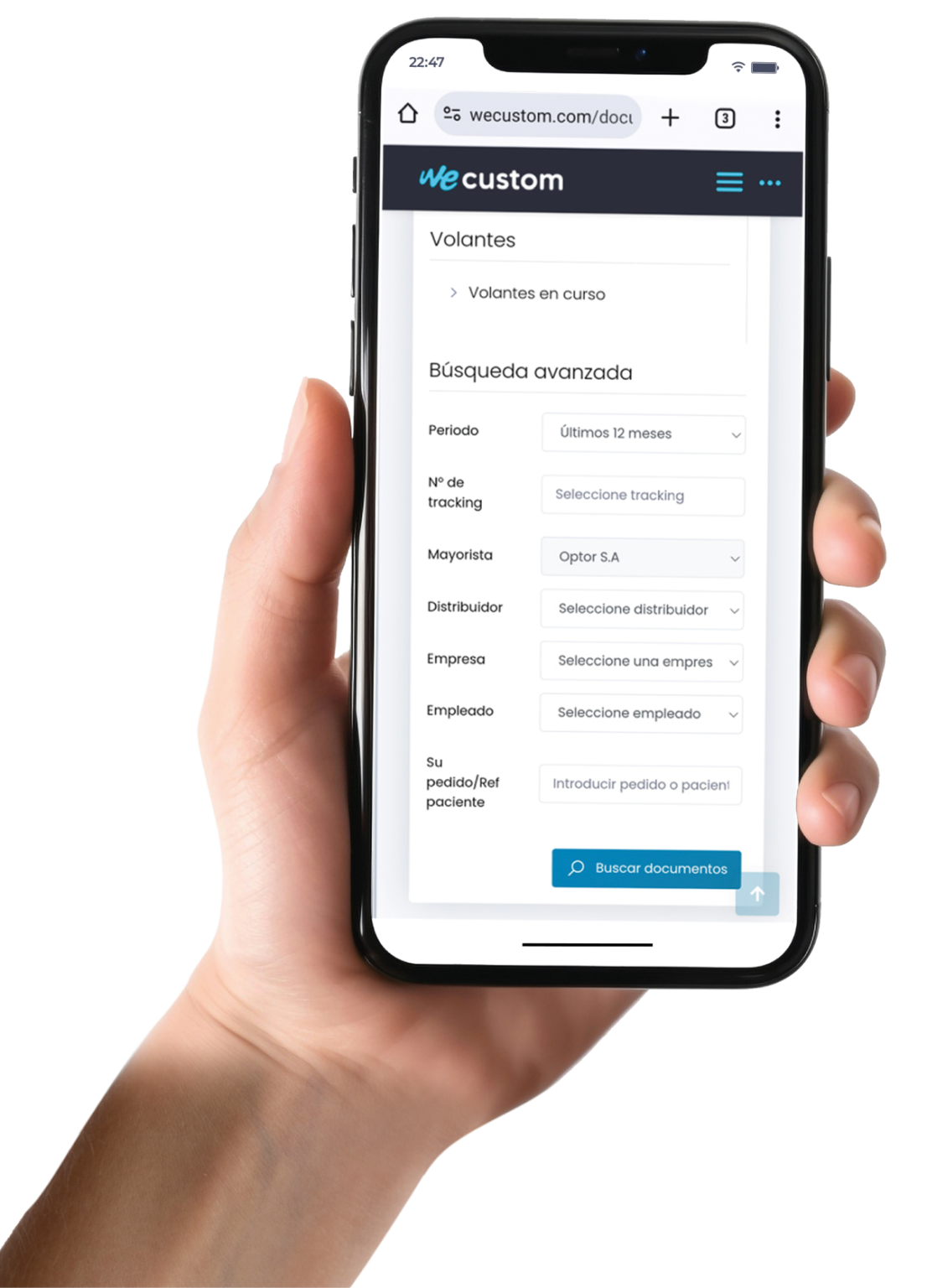

Your prescription safety glasses in one click

Latest TECH performs better

1

The person in charge of HSE in the company fills out the application form.

2

The optician receives the application and graduates the employee.

3

Manufactured in

7 working days.

Pegaso for companies

Contact us and rely on more than 65 years of experience in occupational safety and eye protection.

Fernando García

Sales Managerfgarcia@pegaso.es

Tel: 932 04 81 10

Vicente Soriano

National Sales Representative España & Portugalvicente@pegaso.es

Tel: 932 04 81 10

Protect your eyes without sacrificing style

At Pegaso Safety we know that looking good is as important as being protected. Our wide variety of prescription safety glasses are designed to fit different faces, styles and work activities. We spend much of our day at work, and safety glasses that you like can make all the difference. Discover our range of prescription safety glasses for work with a variety of features.DESIGNS WITH SIDE SHIELDS

INTERIOR FOAM PROTECTION

OFFICE PROTECTION

TEMPLES COMPATIBLE WITH OTHER EPIS

Frequently asked questions about prescription safety spectacles

How to choose the right safety glasses for your work?

| Eyes are fragile and highly vulnerable organs; even a superficial irritation can cause minor injuries or, in some cases, irreversible damage. For this reason, not all commonly used goggles are effective in protecting them against hazards such as particles, chemical splashes or welding sparks. It is crucial to opt for safety glasses that are robust and specifically adapted to the needs and hazards of the working environment. To do this, the first step is to analyze the risks associated with your professional activity and select the type of protection that best suits them. |

Types of safety glasses according to occupational hazards

| To ensure effective protection, it is essential to analyze the specific risks to which we are exposed. Depending on the type of risk, safety glasses can be classified as follows: |

| Mechanical risk: Designed to protect against impacts from solid particles. |

| Chemical or biological risk: They provide a barrier against chemical splashes and exposure to microorganisms. |

| Electrical risk: They offer protection against UV rays, heat and particles generated in electrical environments. |

| Thermal risk: Suitable for protection against hot particles and intense radiation, such as those produced by welding or extreme heat sources. |

| Radiation risks: They protect against infrared (IR), ultraviolet (UV) and laser radiation. |

| In addition, specific treatments can be incorporated to increase their functionality: |

| In humid environments, an anti-fog coating is essential. |

| For activities that require greater durability, it is useful to add an anti-scratch or anti-reflective treatment to improve vision and extend the life of the eyewear. |

| Selecting the right eyewear ensures optimal protection and increased safety in the work environment. |

Safety glasses certification

| Safety glasses must be properly certified, with clear markings indicating the level of protection they offer. These markings are present on both the lenses and the frame. At Pegaso Safety, all our models comply with current regulations and have the corresponding markings, making it easy to identify the most suitable spectacles for your work needs. Check our guide to markings and regulations to find the ideal model that meets the safety requirements of your work environment |

We help you choose your safety glasses

| We understand that choosing the right protective eyewear may raise doubts, either about the specific features and characteristics of each model or about the applicable regulations. Aspects such as the type of filter required or the most suitable type according to your professional activity can be confusing. To make this process easier, we have prepared a video that shows how simple it can be to select the ideal glasses for your job. And if you still have questions or need advice, our customer service team is available to guide you through every step of your choice. |

What type of lenses are best for safety glasses?

| The choice of the most suitable lenses depends on the activity you perform and the risks you are exposed to. Among the most common options are: |

| Polycarbonate lenses: These are highly resistant to impacts, high temperatures and scratches, making them the most commonly used option in neutral safety glasses. |

| Organic or mineral lenses: These offer greater resistance to chemical products, making them ideal for environments where corrosive substances are handled. They are often used in prescription safety glasses. |

| Selecting the right material will ensure efficient protection and optimum performance in your work environment. |

How to choose the right working glasses?

| With the wide variety of safety glasses available, it is essential to select those that best suit the type of work and the specific risks of the work environment. In our catalog you will find options with organic lenses, polycarbonate and other materials, each designed to meet different requirements. |

| Some recommendations according to the activity are: |

| Protection against corrosive liquids and chemicals: Opt for Goggle-type glasses, which offer complete sealing and superior protection. |

| Welding : be sure to choose safety glasses with the right DIN filter for the type of welding you will be doing. |

| Construction: Goggles with integral or universal prescription frames, complemented by side shields, are ideal for protection against particles and debris. |

| Selecting the right goggles not only ensures worker safety, but also greater comfort and performance in the performance of your tasks. |